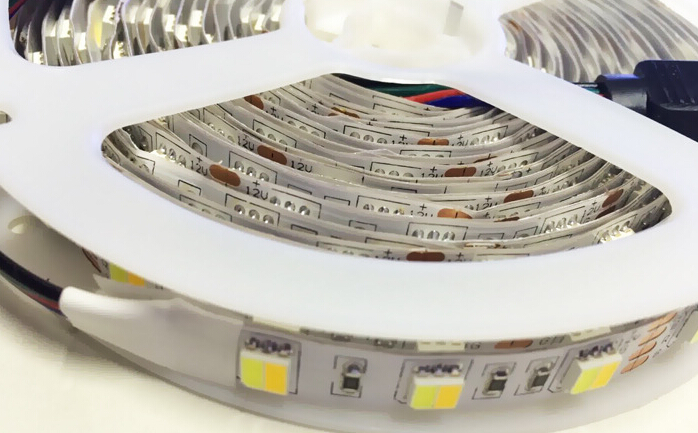

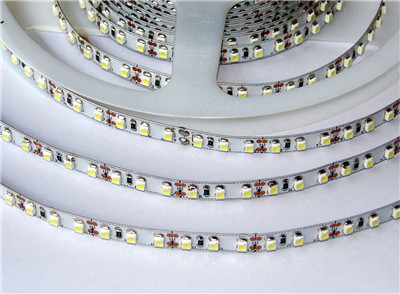

3528 high-pressure lamp with

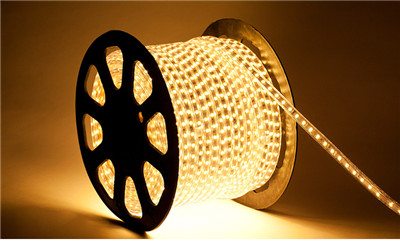

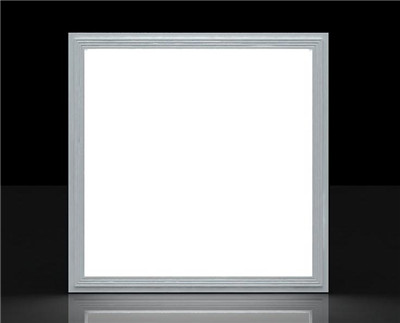

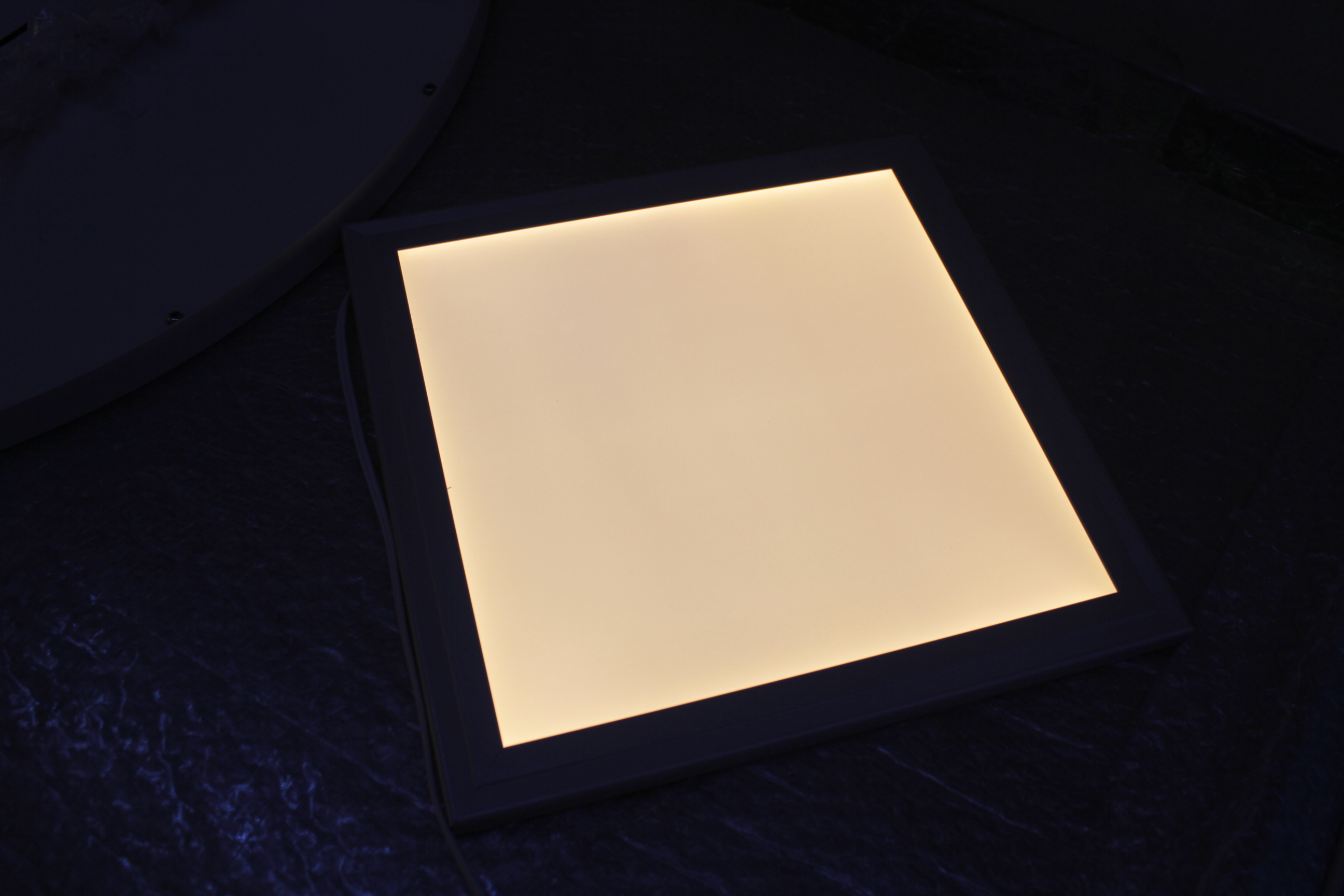

3528 high-pressure lamp with 300 * 1200mm Panel Light

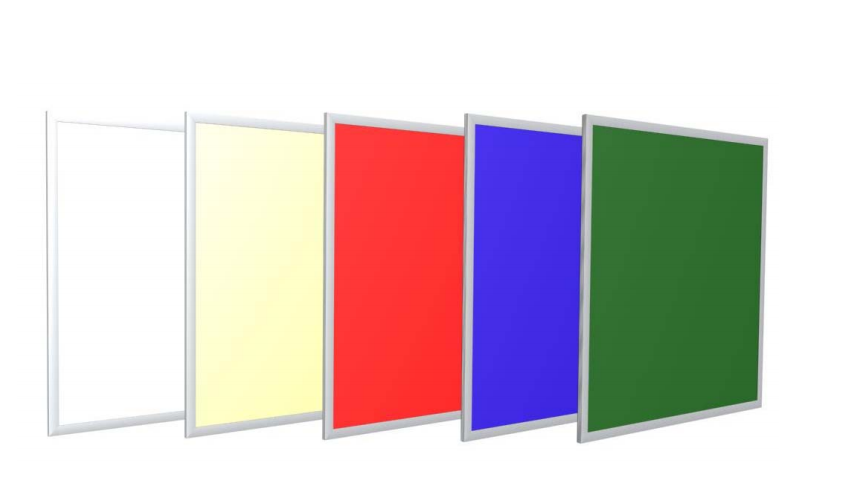

300 * 1200mm Panel Light 5050 RGB lights with high pressure

5050 RGB lights with high pressure 5252 color lights with high pressure

5252 color lights with high pressure Glue deep waterproof lights

Glue deep waterproof lights Single-lamp color temperature lights

Single-lamp color temperature lights 5050 color temperature lights

5050 color temperature lights 5050 60 lights filling plastic

5050 60 lights filling plastic 5050 60 lights casing

5050 60 lights casing 3528 240 Lights

3528 240 Lights 5050120 Lights

5050120 Lights 5050 RGB low-voltage lights

5050 RGB low-voltage lights 3528120 Lights

3528120 Lights 5050 Blu-ray high-voltage lights

5050 Blu-ray high-voltage lights 5050 High-voltage lights

5050 High-voltage lights 600mm * 600mm panel light

600mm * 600mm panel light RGB Panel Light

RGB Panel Light Color temperature adjustment panel light dimmer

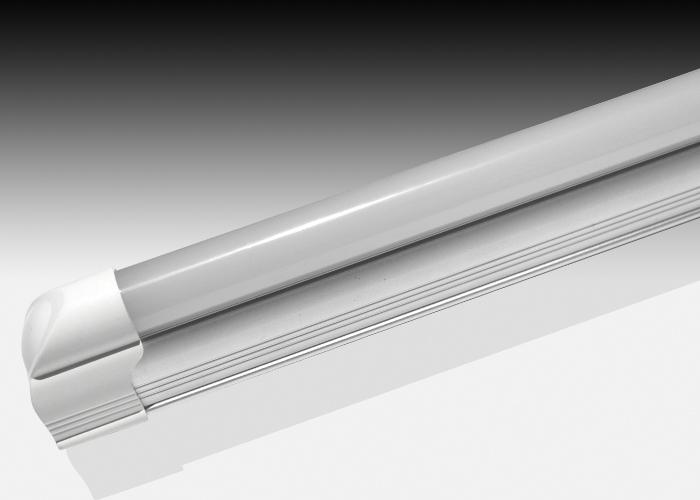

Color temperature adjustment panel light dimmer T8 single tube

T8 single tube T5 Integration lamp

T5 Integration lamp SMD5050 Epoxy lights

SMD5050 Epoxy lights 240 mm* 16mm Round panel lights

240 mm* 16mm Round panel lights Round color panel lights

Round color panel lights

LED power LED lamp is a very important part, if the improper selection, LED lamp not play his rightful property, and even may not work properly lighting. Here I LED fluorescent lighting made some small suggestions for your information

Currently, LED fluorescent lighting market more active, LED driver power supply manufacturers are mainly divided into three major types: The first is the development of LED chip or LED lights do plants, homeopathic downstream penetration; the second is to do is to do the original general lighting factory ; The third category is entirely newly opened factory, they have done before the power supply or other product or new business.

1, LED fluorescent lamp power Why must constant it?

Characteristics of LED lighting decide influenced by the environment, such as temperature, LED current will increase; increase of voltage, LED current will increase. Long-term than the rated current work, will greatly shorten the life of the LED. The LED constant is change when environmental factors such as temperature and voltage, to ensure that the operating current constant.

2, LED fluorescent lamp power to how we can match the light board?

Some customers to design the light board, find the power, find it difficult to have a suitable power supply, or too much current, the voltage is too small (as I>

350mA, V

3, LED fluorescent lamp power supply operating current is how much is the most appropriate?

General LED rated operating current 20 mA, some plants used to make the design 20 milliamps actually working under this current heat is very serious, after repeated comparison test, designed to be 17 to 19 mA compare Ideal recommended is 18 mA.

4, LED fluorescent lamp power supply operating voltage is how much?

General LED's recommended operating voltage is 3.0-3.5V, has been tested, most of the work in 3.125V, 3.125V calculated according to the formula so reasonable. M light bead series total voltage = 3.125 * M

5, series-parallel LED light board with wide voltage to how wide it?

For LED lamp work in a relatively wide range of input voltage range (full voltage) AC85 ~ 265V, the panel LED lamp series and parallel is important. Due to the current supply is generally non-isolated buck power supply, wide voltage, the output voltage should not exceed 72V, the input voltage range of 85 ~ 265V can reach. That is, the serial number no more than 23 strings. Parallel Number not too much, otherwise the operating current too serious fever is recommended for 6 and / 8 and / 12 and. Total current not exceeding 240 mA as well. There is also a wide voltage solution is to first use the L6561 / 7527 a voltage is raised to 400V, then the buck, the equivalent of two switching power supply, cost twice as expensive, this program cost is not high, there is no market.

6, LED series and parallel relationship with PFC power factor and wide voltage is what?

PFC power supply on the market at present, there are three cases: one is dedicated circuit without PFC, which PFC is generally about 0.65; a band passive PFC circuit, the light board horses prepared well, PFC generally about 0.92; also is active with an active circuit made of 7527/6561, PFC can reach 0.99, but the cost of this program is more expensive than doubled in the second program. So many second option. For passive PFC circuit: also called valley fill PFC circuit, the operating voltage range of the AC input voltage peak half. If the input is 180V, the peak is 180 * 1.414 = 254V, half the peak voltage is 127V, the buck minus differential pressure 30V, maximum output is 90V, so the maximum number of series 28 LED lamp beads string. Therefore, to obtain relatively large power factor, number of series lamp beads not too much, otherwise, it can not reach the low voltage.

7, LED fluorescent lamp power supply current precision how much would be most appropriate?

Some current precision on the market power of the poor, like the popular market PT4107 / HV9910 / BP2808 / SMD802 programs constant program error of ± 8% or ± 10%, constant error is too large. ± 3% generally require it. Press 3% error, 6-way parallel, each of the error is about ± 0.5%, if the 12-way parallel, each of the error is about ± 0.25%, the accuracy is sufficient. Accuracy is too high, the cost will be greatly increased. And in terms of LED, 17 mA and 17.5 mA little effect.

8, isolation / non-isolated

Usually made of isolated power as 15W, placed in LED lamp, its transformer bulky, difficult to put in here. Especially for T6 / T8 lamp, almost impossible, so the isolation of the general can do 15W, 15W more than the small, and the price is very expensive. Therefore, the isolation of cost is not high, the general non-isolated more mainstream, the volume can be made smaller, the minimum can be done 8 mm high, in fact, non-isolated safety measures well, is not problematic.

9, LED fluorescent lamp power supply efficiency

Output power (output LED voltage * Output current / input power). This argument is particularly important, if inefficient means that a large part of the input power is converted into heat that comes out; if it is contained within the tube will produce a very high temperature, combined with our LED light efficiency than the one dissipate the heat, it will produce a higher temperature superposition. Our electronic components inside the power supply for all life will be shortened with increasing temperature. So efficiency is to determine the power life's most fundamental factor, efficiency is too low, or the power consumption of calories too. Generally above 80% can, however, about the efficiency of matching the lamp plate connection.

10, LED fluorescent lamp power supply Dimensions

Height is the main limiting factor, generally used for T6 tube / T8 size requirements ≤9 mm height is not too high. T10 tube height ≤15 mm. Length can be rather long, but easy to heat.